|

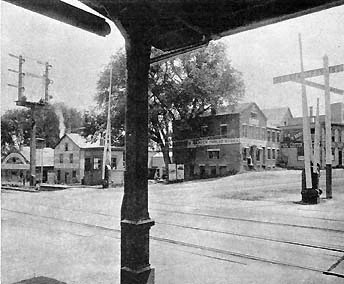

W. Warren Thread Works - Viewed Across the River.

W. Warren Thread Works.

This is the title of one of Westfield’s most enterprising and prosperous manufacturing concerns. The business was established at Westfield in 1880, by William Warren, on the upper floor of a small building near Elm street bridge, and rapidly developed. Five years later his son, W.P. Warren, was taken into partnership and for some years has managed the financial affairs of the firm with G.L. Manning as superintendent of the manufacturing.

From an upper floor in a small building the business has grown, to occupy seven buildings within a stone’s throw of the passenger stations and freight houses of the Boston and Albany, and New York, New Haven and Hartford railroads; and from employing six hands to employing ten times that number in Westfield and some two hundred at the mill in Rhode Island where the yarn is made which at Westfield is converted into thread. For quite a time after the industry was started only whip thread was made, and although this branch is now but a small part of the business, the factory turns out fully nine-tenths of all the whip thread used in the United States. Cotton yarns, threads, cords and spool cotton of every description used by manufacturers in making underwear, boots and shoes, clothing, hats and ribbons and a variety of other articles forms the bulk of the factory’s product. Within the past two years a dyeing department has been added to the plant, admitting of the firm not only dyeing their own cotton yearn, but also large quantities for other mills. Robert Irving, an experiences Scotch dyer, has charge of this department.

W. Warren Thread Works, Westfield.

This was the first concern in Westfield to put electric lights into their buildings and a phonograph, typewriter and electric clock into their office. It indicates their progressive character and constant watch to secure every modern improvement in their business. Before locating in Westfield, the senior partner was for a dozen or more years engaged in thread manufacturing in Worcester, and the junior partner managed the New York city salesroom. Superintendent Manning is one of the oldest thread makers in the country, in point of service, having been engaged in the business since 1850.

|

A Cone of Thread.

The Foster Machine Company.

This corporation was formed early in 1891, with a capital of $150,000, removing from Springfield where only a dozen men were employed. But since the plant was moved to Westfield and to the commodious brick buildings especially erected for it, sixty hands have been employed.

The officers of the company are: President, W.P. Warren; treasurer, G.E. Manning; superintendent, John Foster; assistant superintendent, A.W. Warren.

The output of the works is special textile machinery, such as patented cone and textile tube winders and twisters used in cotton, silks, worsted, wool, and linen mills. All the various machine made by the company are patented inventions of John Foster, the superintendent, who is a genius in this direction. The company has recently purchased from Brooks & Doxie of Manchester, England, the sole right to manufacture in this country the Brooks Cone and Tube Winder. The English concern has a large business in the United States, which the Foster company will now control and thereby be greatly benefited, as the English machines for this country will be made in the Foster company’s shops.

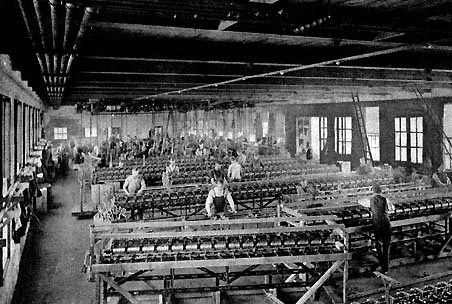

A new machine has been lately perfected by Mr. Foster that will be much appreciated by yarn manufacturers, when placed on the market. The machine will twist from bobbin, cap or spool direct on to paper cones or tubes, all in one operation. The growth of the business has even exceeded the most sanguine expectation of its projectors and next spring a two-story brick building is to be added to the plant. The illustration shows the interior of the setting-up department 50 by 100 feet, and a cone of yarn on a paper cone as wound on the machines manufactured at these works.

Interior of a Room in the Works of the Foster Machine Company, Westfield.

|