The machine room is a noisy place and I can remember as a little fellow the half fright and awe with which I passed through this room, the machine is so big and complicated and so loud in its clattering. The floors are wet and steamy vapors are rising from the damp paper, and the air here is warm and moist, whatever the outside weather. A machine is about a hundred feet long. At one end a little stream of pulp is allowed to flow in, varying in volume with the weight of paper desired. It is mixed with a stream of water that reduces it to a thin, milky fluid, that seems to be so nearly water that one doubts the possibility of ever getting such stuff into solid sheets of paper. All this end of the machines is in a violent, jarring motion to distribute the paper fiber evenly. Presently the fluid flows on to a long strip of revolving wire cloth and begins to lose its water. Fifteen feet distant, almost as if by a miracle, the substance flows away a solid, broad sheet of paper.

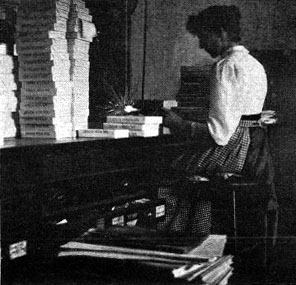

Sealing.

|

The moist sheet now passes beneath a revolving roll of wire, which bears on its surface raised letters and, perhaps, certain designs, and these stamp what is known as the water-mark on the paper. You can see it if you look through a sheet held against the light, but it is not usually apparent otherwise. After a little further progress, you find the paper has become dry and hard. Lastly it passes through a vat of gluey animal sizing and under a revolving cutter and is delivered at the end in fast falling sheets of the size desired. The paper then goes into the loft to be dried. The sheets are hung over poles in folds of ten or fifteen in a bunch, until a room is filled from floor to ceiling. Then steam is turned on and it is allowed to dry for forty-eight hours. It does not look very handsome as it comes from the lofts, it is so wrinkled and rough that you begin to think it’s a failure after all, when the calender girls get it and run it through their machines and it comes ut as fair and as smooth as you please. Next the sorters take it. They sit at their table and keep the sheets swiftly turning — the perfect sheets being put in one pile, the slightly imperfect in another, and the more defective, which must be ground over, in a third. A counter takes the sheets and runs over them rapidly and lays them off in reams to be trimmed and wrapped for the market. The last work is that of the sealer who, with a stick of wax and a lighted gas jet, accumulates the neatly packed packages about him or her with astonishing rapidity. If the paper is to be put up in boxes, it has to be cut into small sheets and perhaps passed through a ruling machine. Then it is folded, pressed and banded. Enveloped have to be made to go with it, and it is interesting to watch the machine, which takes the queerly outlined sheets cut for it and folds and gums and shapes them into envelopes. The girl at the machine counts and bands them, and another takes them away and puts them and the paper up in the pretty boxes awaiting. And now they are ready for the final packing and shipment to stationers the world over.

If this story were a bit of newspaper advertising, the reader would find a moral at the close something like the following: "When next you need stationary, Buy Whiting’s Standard." As it is, I leave the readers to draw their own moral, provided they can find one.

It may be of interest to note that the product of fine writing papers, sent out by the Whiting company, is larger in amount thatn that of any other mill in this country. What I have so far written has had special reference to the boxed papers sold by stationers, but that is only one branch of the industry. The firm makes ledger papers, bond papers, linens—in fact all the varieties of first-class papers which are called for by the general paper trade.

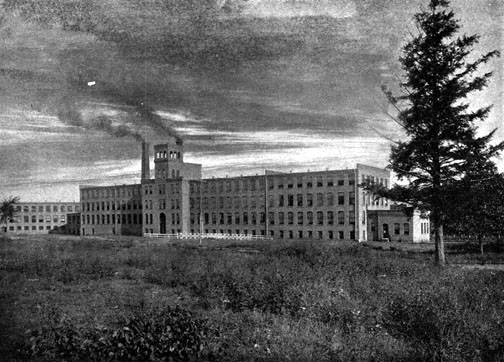

The company has three mills, two in Holyoke, and the other on the Chicopee river at Wilbraham, Mass. They would all be ranked as large mills, even in an industry noted for its immense buildings. Then, too, it is to be mentioned that the corporation, large as it is, has very few stockholders. The stock is, in fact, alll owned in two families, the Whitings of Holyoke and the Jenks family of Adams.

The Mill of the Whiting Paper Company, at Wilbraham, Mass.

© Laurel O’Donnell 1996 - 2006, all rights reserved

This document may be downloaded for personal non-commercial use only

and may not be reproduced or distributed without permission in any format.

This is an edited adaptation from the original publication.

|