|

In the Engine Room.

|

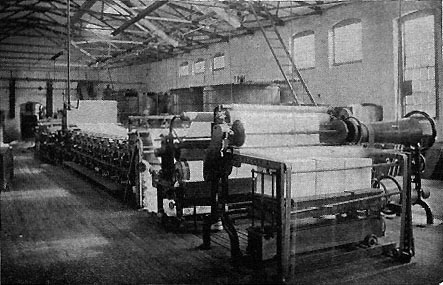

The Paper Machine.

|

From this hopper they are dropped through a hole in the floor, and if we follow them — not through the hole, but down the stairway — we enter a large room where a little army of "girls" is at work amidst a great array of immense baskets heaped to overflowing with the white rags. By "girls" I do not mean children. A woman is always a "girl" in the mill, whatever her age. The women wear a sort of uniform in this room. At least each has a little blue cap and apron. Most of them stand facing the windows before a wide continuous table divided into apartments and floored with a coarse wire screen. In front of each girl is a heavy upright knife like a broad-bladed scythe, which they use to cut off buttons with. Behind her are tow or three baskets into which the different sortings are thrown. From the "Screen girls" the rags go for a more careful sorting to the "Table girls." The heavily loaded baskets filled by them are slid into a little side room where the cutter is at work. A single girl feeds the rags into the low, rattling, grinding, jarring machine that, six feet from the starting point, delivers them all cut in one to three-inch squares at the rate of a ton an hour. Until within a short time this work was done by hand on the knives in the room adjoining. The center drops the rags on a revolving strip of canvas which carries them down stairs, and lets them fall into another dusting machine. This machine is a huge drum of wire netting inside a box or small room. Lift a door and look in and you see the rags rolling about within the drum, and below a thick deposit of linty "dust." The "dust" is nearly white and looks quite good enough for fine paper, but it is all sold to mills which manufacture the coarse paper used under carpets. The rags pass through three of these dusters one after another and then are caught on a strip of canvas which hurries them up to the ceiling, there to toss them down a steep incline of iron slats. Through this such stray buttons as have passd the sorter are supposed to fall. A vigilant watch is kept for buttons up to the last moment and there are many little devices for detaining them, so that there is a small danger of a customer’s finding any in his paper.

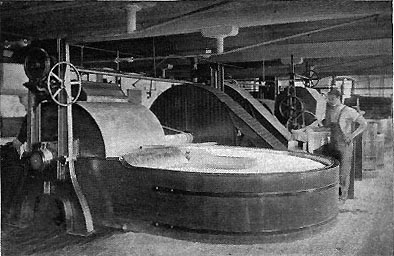

After the dusting, the rags are pushed down through a convenient hole in the floor, which lets them fall into an immense cylinder tank or iron which holds fully three tons. A mixture of lime water and soda ash is put in with the rags and the steam is turned on. In this slowly revolving tank the rags are boiled for twelve hours. They look to be well-cooked by the time they come out, for they have turned to a rusty brown. Numerous big boxes mounted on trucks are being trundled by the workmen to the sloppy floors of the boiler room to the apartment adjoining, where they are thrown into great oval vats known as "engines." Each engine is furnished with a heavy, revolving iron wheel slatted with knives, which keeps the contents of the vat in motion and tears them to bits. A stream of water is turned on, and this water, though it came originally from the near canal, has been filtered to a purity that, if one tries it, will be found in taste and quality fully up to spring water. Chloride of lime is added for a bleach, and after six hours working over in this tank the contents are very white and pulpy. Still, this is only the beginning. For a full week this pulp is allowed to soak in great tanks of bleach and then is ready for a final grinding. It comes from the bleach of a delicious whiteness and looks good enough to eat. A paper pulp pudding, if it tasted as good as it looked, would be a rare dish. Now the pulp is washed in one of the engines and freed from the chloride of lime, and is kept grinding for ten hours more before it is ready for the paper machine. Meanwhile, color has been added and alum to fix it, and now it goes down to the basement to the "chest." The chest is a big vat, with long arms revolving within to keep the contents stirring, and from this the pulp is pumped up to the "machines."

|

The Calenders.

|

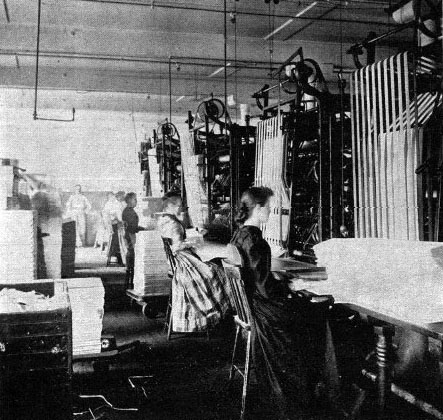

Sorting.

|

© Laurel O’Donnell 1996 - 2006, all rights reserved

This document may be downloaded for personal non-commercial use only

and may not be reproduced or distributed without permission in any format.

This is an edited adaptation from the original publication.

|

|

|