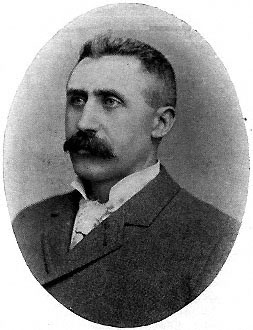

The Late David F. Coghlan.

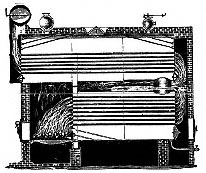

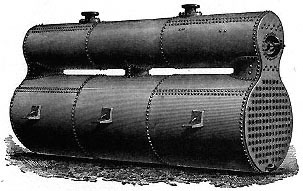

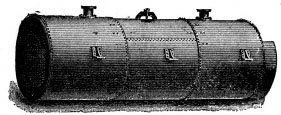

End View of the

Sears Double-Deck

Tubular Boiler.

Side Elevation of

The Sears Double

Deck Tubular Boiler.

Compound Tubular Steam Boiler.

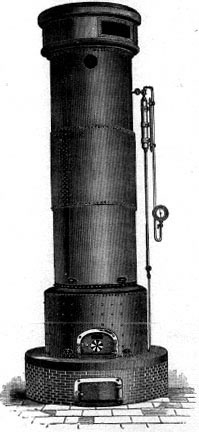

High-Pressure Manning Boiler.

Improved Tripe Draught Tubular Boiler.

|

The Holyoke steam boiler works are situated in convenient proximity to the railroads running through Holyoke and cover an area of nearly 30,000 square feet in a triangle formed by the conjunction of Park and Crescent streets.

We read that Jubal Cain was a "man of might," and his prototypes of the present age at these works are mostly after his pattern, though they have the aid of modern appliances to swing the heavy plates of iron about with a load of plate-iron runs up alongside the shop, a huge crane seizes the metal and swings it around to the bench where the preliminary marketing is done before it goes to the punch. From the punch to the planer, where the rough edges are taken off, and thence to the rolls to be bent, are steps in sequence. When the rolls have turned the plate to its proper circle, it is placed on the floor and connected with the other parts which go to form the completed structure, and the seams are riveted together.

Plain Horizontal Tubular Boiler

|

The tube sheets are now flanged, drilled and riveted into place, and the castings for the nozzle of the steam outlet, the manhole and the wall brackets to support the boiler are attached; the braces to hold the unsupported part of the tube sheets are riveted on, and finally the tubes are placed in the boiler and carefully expanded.

After the tubes are set and the boiler joints calked, an inspector of the Hartford Steam Boiler Inspection and Insurance Company is called in, and in his presence the boiler is filled with cold water and submitted to a hydrostatic pressure of two hundred and twenty-five pounds. If by this severe test no weakness is discovered, the boiler is certainly safe, and it is a fact that no explosion, rupture or strain, which sometimes result from poor construction and bad material, has ever occurred in the Coghlan boilers. Among papermakers throughout the country the rotary bleacher manufactured at Coghlan’s has found especial favor, and while it is so nearly perfect to-day that it seems as if the limit has been nearly reached, yet it is being continually being subjected to improvements, so that while the rotary of five years ago was the best of its kind then on the market, the rotary of to--day is far better than that, and the rotary of five years hence will be in advance of this. The important particulars in which the present differs from the old style of rotary bleachers are the substitution of the full plate for the sectional head and the application of a patent blow-off and strainer, together with the method of connecting the rag-pins, which is covered by letters patent. The spur-gear system or driving apparatus of this machine makes it the easiest running rotary extant.

This establishment also builds a compound tabular steam boiler, a horizontal tubular boiler, the Manning vertical boiler, a triple draught boiler and Sears’ Water-Tube Boiler. The latter is the invention of Mr. T.H. Sears, who obtained a patent for it in 1886 on the points of heat conservation and the means of preventing the collection of sediment in the tubes. These ends are accomplished by a peculiar and ingenious alternation of water and fire tubes by which the water in the former incloses the fire space in the latter, constituting a "central-fire tube water-tube boiler."

The triple draught boiler offers easy accessibility for cleaning and repairing, and as its name indicates, the heat from the combustion is so utilized that the gases make three turns from the fire-bed to the flue, thus bringing the greatest possible extent of tubing surface in direct contact with the heat.

T.H. Sears, Manager of the Coghlan Boiler Works

|

Repair and inspection work anywhere, but especially in New England and eastern New York, form no small part of the business at Coghlan’s. The former is intrusted only to skilled mechanics, while to the latter Mr. Sears gives his own personal supervision, and in both cases the demands of the highest standard are exemplified in the results attained.

The facilities of the concern for doing everything in firstclass plate iron work are so well known that it has been crowded to overflowing, through the past season, with the accumulation of orders, and the concern now has more workmen employed than at any time in its history, probabilities being that its number will be still further increased.

About 65 men are employed by the Coghlan boiler works, and the pay roll amounts to about $3,6000 a month.

|