Fenton & Dunn, Carriage Manufacturers.

Factories of Fenton & Dunn,

Corner Hampden and Walnut Streets, Holyoke.

Among the carriage makers of New England, one of the youngest, and yet one of the most prosperous and popular is their firm of Fenton & Dunn of Holyoke. Established but nineteen years since, they have reached a position in the trade which many older concerns have failed to attain, and this is mainly because of the best workmanship and constant, close, personal attention of both members of the firm to those many details which go to make up the business.

The firm occupies to-day the same lot of land it started up in in 1873, at the corner of Walnut and Hampden streets—only it uses more of it. The one small shop the company used at first is now occupied as a barn, and the premises were enlarged four times to accommodate the constantly increasing business, until in 1888 the plant reached its present dimensions of about 40,000 feet of floor space.

Both Messrs. Fenton and Dunn are practical mechanics, and started at the anvil and forge, making carriage irons. Mr. Fenton came from Maine, of which state he is a native, and where he began an acquaintance with his trade, and coming to Holyoke he met Mr. Dunn (a native of this state), in trade acquaintance and further apprenticeship until the two felt able to "paddle their own canoe," — something which subsequent events have shown they could do most successfully.

Both gentlemen are now about forty years of age, evidently fairly established in a successful business career, and an adherence to their business practices and customs in the past would seem to be all that is needed to insure the crowning triumphs of a diligent business life. We speak advisedly when we say that this company make only the finest of work — their reputation all through the line of their patronage bears out this statement. All parts of their carriages and wagons are put together to stay; the irons are wrought with care and the wood is the most select, choice and toughest of stock, so that when one hears of any part of Fenton & Dunn’s carriages breaking or wearing out, he may be pretty sure it is not the fault of the stock, and that no other carriage maker’s work could have stood the same amount of strain any better. This company never sold any carriages not made by themselves, and customers therefore have their carriages practically built to order. The works are running full at all seasons of the year — something that cannot be said of carriage makers’ shops generally. They average an employment of one hundred men and these workmen are the best mechanics of their class in New England.

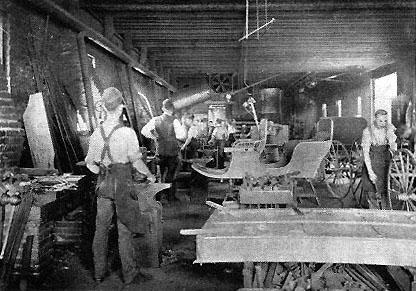

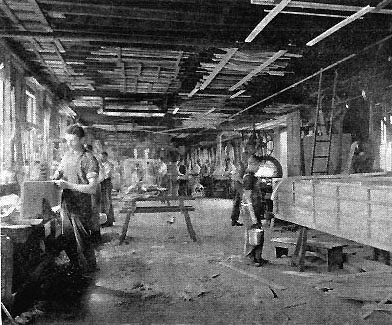

The shops are equipped with a steam plant and all needed modern machinery, and sections of two of the most interesting departments are shown in engravings on this page. The wood used in the productions of this establishment is picked up with great care all over New England, and consists almost entirely of hickory, oak and ash.

New England furnishes most of the customers for Fenton & Dunn’s work, but one of their specialties, hose wagons, is called for all over the country. In this line they turn out a machine which delights the heart of a fireman.

A visit to the ware rooms of the company by prospective customers is always welcomed by the firm, and the pride which the proprietors show in their productions, with their evident conscientiousness generally impresses one so favorably, that if one is earnestly desirous to buy, he is likely to make a bargain; for it is something, in the midst of much sham and pretense, to find two young business men who have built up a reputation for producing the best, so wide and far-reaching that no one questions it.

A Section of the Blacksmith Shop.

|

A Section of the Wood Working Department.

|

© Laurel O’Donnell 1996 - 2006, all rights reserved

This document may be downloaded for personal non-commercial use only

and may not be reproduced or distributed without permission in any format.

This is an edited adaptation from the original publication.

|