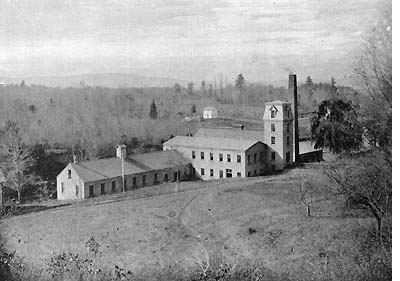

Crane Bro’s Paper Manufacturers.

CRANE BROTHERS’ name has become indelibly associated with the work of paper manufacturing in Western Massachusetts, and this is solely because of their superb Ledger and Record papers, which have no superior in their kind, while many consider them immeasurably beyond anything elsewhere produced.

Main Mills of Crane Brothers.

|

The first paper maker of this now notable family, Zenas Crane, established his mill in Dalton in 1801, and they are his grandsons, J. Arthur and Robert B. Crane, who are now keeping green the family name in Westfield. They are paper makers by hereditary liking, having mastered the rudiments of the trade in the mills of Crane & Co. They began business in a modest way at Westfield in 1868, and have been continually enlarging their mills, this year making still another important addition, which, partially completed, shows on the right ot the upper engraving on this page. The capacity of the original mill has been more than quadrupled.

The main group of mills is situated two miles from the Boston and Albany, and New York, New Haven and Hartford station in Westfield, while the smaller mill is a mile or so farther up the stream, a small river having its source in the hills at the west. A spur track connects the mill with railroads running to all points of the compass. The central building of the main group is the original mill known as the "Japanese" mill. The manufacture of the famous "Japanese Linen" is now, however, carried on at the "Glen" mill, as also is the "Warranted All Linen" brand, while the Japanese mills are used exclusively for the Gold Medal Linen Ledger and Record papers. This mill is shown separately.

All rags used are cut by hand, as the quality of goods made require this treatment, machine cutting being available for lower grades of paper only. The proper length of fibre can only be obtained by this process of hand cutting. The usual processes of dusting prevail, but after the last dusting, still further inspection by hand is necessary to ensure perfection before the alkali is applied for bleaching.

Special attention is given in the beating engines, after the pulp has been washed, according to the paper to be made, five to ten hours being necessary in ordinary writing paper and from twelve to twenty-four hours when Ledger and Linen papers are made.

When the pulp goes into the stuff-chest it represents the sum of all that human knowledge, patience, ingenuity and watchfulness can do toward the preparation of the material for a paper that shall be clear, even and solid in its substance, strong in its fibre, with an easy writing surface, and, what is of great importance in ledger and record books, capable of erasure without destruction of the writing surface; and it is one of the achievements on which Crane Brothers especially pride themselves that an erasure on their ledger and record paper requires no pumice or rubbing to smooth it for rewriting. The Ledger and Record papers are made in all the standard sizes and weights, from 15 X 19 inches, and weighing 22 pounds to the ream, through the different sizes and weights of Demy, Medium, Royal, Super Royal, Elephant, Imperial, Double Cap, Double Demy, Double Medium, Double Royal, Colombier, Atlas, and Double Elephant, the latter 27 X 40 inches and weighing 125 pounds to the ream, while a still larger and heavier size is Antiquarian, almost as thick as cardboard, 31 X 53 inches and weighing 200 pounds per ream.

One peculiarity obtains in this mill in reference to the water-marks. Reputation for quality in any line is a great desideratum, and Crane Brothers are fully alive to the importance of impressing upon every consumer of their goods the fact that they maintain a degree of excellence not surpassed. While many paper makers introduce a water-mark into their papers, they often do so in a haphazard sort of way, impressing the paper in any situation, regardless of uniformity or regularity. Every sheet of paper made in this mill is water-marked with their trademark in the same place on each sheet, and in binding or ruling, with but little care each sheet will show the mark right side up and facing the observer.

The ‘Glen Mill’ of Crane Brothers, Westfield, Mass

|

Years ago the tendencies of trade were recognized by Crane Brothers, and to protect themselves they adopted and patented the crane as their trade-mark.

Another important point finds its highest exemplification in these mills. The absolute necessity for good water in making paper is probably well known, but pure water is almost impossible in many localities. The Crane Brothers have as nearly pure water as is obtainable, conveying it from springs in the mountains and insuring more than ordinary cleanliness. In fact, a poorer water would not allow the making of such grades as they produce.

In order to demonstrate the reputation the papers made here possess, it is only necessary to note their phenomenal success in prize competitions. The highest award for record paper was obtained at the Centennial exposition at Philadelphia in 1876, grand prize gold medals were received at the Paris exposition of 1878 and at the Melbourne exposition in 1880. The New Orleans World’s exposition of 1885 awarded the grand prize gold medal. A diploma was received from the American Institute in 1890, and a bronze medal from the Franklin Institute of Philadelphia in the same year, while the highest award was given at Berlin in 1878, and Mechanics Institute, Boston, 1890.

While paper making is the prime feature of these mills, yet the manufacture of wares of a multitude of varieties from linen waste is now of much importance. This line of goods is known as Linenoid. Over twenty years ago this firm made paper belts for large and small pulleys. The belts used on the large pulleys are very serviceable, as is illustrated by the use of one which has been for fifteen years on five-foot pulleys in the mill of Crane & Co., Dalton. These belts are now made to order only. The variety of goods made from linen waste comprises an elegant line of canoes and other small boats, domes for observatories, resistance boards for electricians, coverings for account books, toboggans, trunks, valises, hand bags, telescope tubes, fire buckets, baskets of all kinds, bath and washtubs, umbrella holders, knife trays, triangles used on pool tables, beside many other useful articles. The goods made this way are waterproof and seamless and so accumulate no dirt and dust, and can easily be washed out. This branch of the business is growing rapidly especially the boat department.

© Laurel O’Donnell 1996 - 2006, all rights reserved

This document may be downloaded for personal non-commercial use only

and may not be reproduced or distributed without permission in any format.

This is an edited adaptation from the original publication.

|