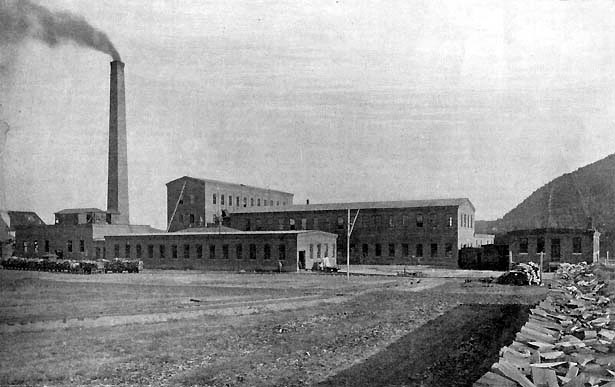

The Mt. Tom Sulfite Pulp Company.

The process of paper making is described with considerable detail in an article at the beginning of this department. Wood pulp was there mentioned as an important ingredient of writing papers, and it will but supplement and complete that article to tell here the Story of pulp making.

The Mount Tom mill, although not in Hampden county, is the only one of the kind in Hampden county vicinity. There are several such in Maine where spruce timber, which is the raw material, abounds; but in central Massachusetts a spruce tree is a rarity, and even back among the hills there are only scattered patches of them. At Mount Tom, however, in close proximity to the pulp mill is located a big lumber company which floats millions of feet of spruce logs, yearly, down from the head waters of the Connecticut. After getting what boards and laths they can from the logs, there still remain the slabs and waste ends, and of these the sawmill itself can make no further use. This is the material utilized by the pulp mill. From the sawmill to the pulp mill a few rods distant runs a little narrow gauge railroad. The loaded cars are pushed by hand or drawn by a single horse directly into the part of the mill where the process of reducing them to pulp is to begin. Here are machines which make quick work of scraping off the bark and such parts as may be decayed, and other machines which bore out the knots. There is left only the clear, solid wood. The sticks are then fed to a voracious monster in the shape of a machine that chews them up into thin, inch-square chips at the rate of nearly ten cords an hour. The chips fall from this machine into an air blast which forces them up a sixty-five-foot pipe to the top story of the digester building. The pipe is of steel, for any metal less bard would be quickly eaten through by the fiercely driven bits of wood.

The interior of the digester building is to the visitor quite impressive. Several immense circular tanks, like upright boilers, rise into the upper glooms of the building. Each of these great steel digesters weighs over forty tons, and when filled each holds eight cords of chips and twenty-eight tons of bisulphite liquor. This liquor the Mount Tom Company manufactures on the spot. To visit this department suggests a descent to the infernal regions described in detail by Dante and certain theologians. The air is charged with sulphurous odors to an extent that very quickly brings the visitor to the sneezing point, and when the lid of one of the curious ovens is lifted a bit that he may look in and see the softly leaping blue flames, he finds it advisable to hold his nose. The fumes of the burning sulphur are passed through five great tanks of lime rock, one after the other, each twenty-two feet high, where they meet and unite with water tricklingdown through and thus form the bisulphite liquor.

Mill of the Mt. Tom Sulfite Pulp Company.

Mill of the Mt. Tom Sulfite Pulp Company.

When a digester has been filled the contents are cooked under seventy-five pounds steam pressure for eighteen hours. Then the contents are drawn off into a big vat whence they are pumped as needed to the washing engines. The material is wood no longer. It is soft and pulpy, light in color, with a slight brownish tinge. The washing engines and the machine over which it is run in making it into paper are the same in plan as those described in the article on paper making. For high-grade papers the pulp, after being washed, is bleached. When shipped the pulp for the most part has been made into a heavy soft paper put up in rolls or bundles. The process requires the use of a vast deal of water, and the Mount Tom Company has in use a pump with a daily capacity of 4,000,000 gallons, an amount more than sufficient to supply a city of twelve or fifteen thousand inhabitants.

The first successful making of pulp by the sulphite process on any large scale dates back about fifteen

but was perfected in Germany. Before that time the alkali process was in use, with poplar wood for the raw material. For most purposes this has been superseded by spruce wood and the sulphite process. Spruce excels for length and strength of fibre. Pine ranks next in quality. The pulp is used in all kinds of paper, but more particularly in the finer grades.

When the improvements now under way are completed the Mount Tom mill will be one of the largest of its kind in the country. Its capacity will be twenty-five tons of finished product per day. In its situation, with its freight conveniences and close proximity to abundant raw material and at the same time to the Holyoke paper mills, with all of which it has direct telephone connections, the mill enjoys unusual advantages. At the same time the location is worthy of remark as one of quite striking picturesqueness. The mill stands on the bank of an old loop of the Connecticut river left stagnant some flity years ago, when the stream cut across the narrow dividing neck of land. On this near water thousands of spruce logs are floating awaiting their turn at the sawmill. Beyond to the south, Mount Tom’s rugged form rises steeply, while eastward, across the river, is seen the long range of Mount Holyoke. On the level near the mills are several boarding houses, and about twenty acres covered with immense piles of slabs. Beyond to the north and west are pretty stretches of meadow land dotted with elms, and far off, glimpses of the blue hills.

The Mount Tom Sulphite Pulp Company is of recent organization and began manufacturing no further back than July, 1891. It has the following list of directors: William A. Russell, president; A. N. Burbank, treasurer; William Whiting, George Van Dyke, Charles C. Springer and Hales W. Sutor. Mr. Springer is the managing director and has general charge and oversight of affairs at the mill.

© Laurel O’Donnell 1996 - 2006, all rights reserved

This document may be downloaded for personal non-commercial use only

and may not be reproduced or distributed without permission in any format.

This is an edited adaptation from the original publication.

|